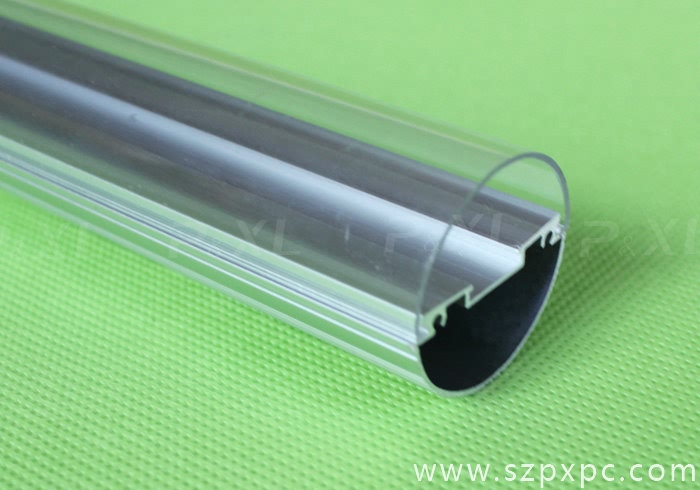

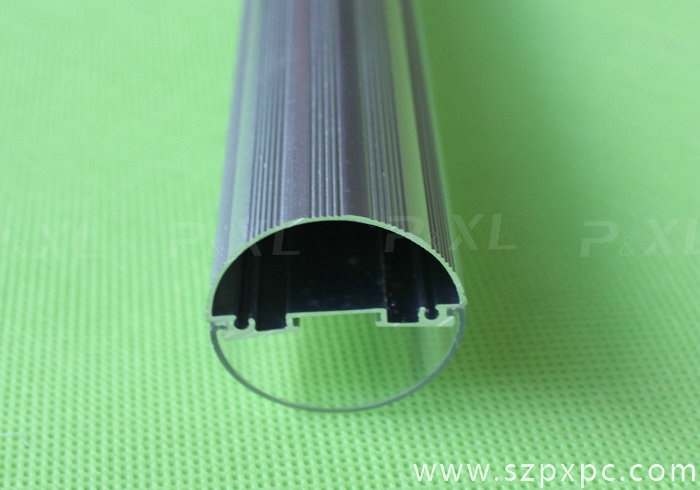

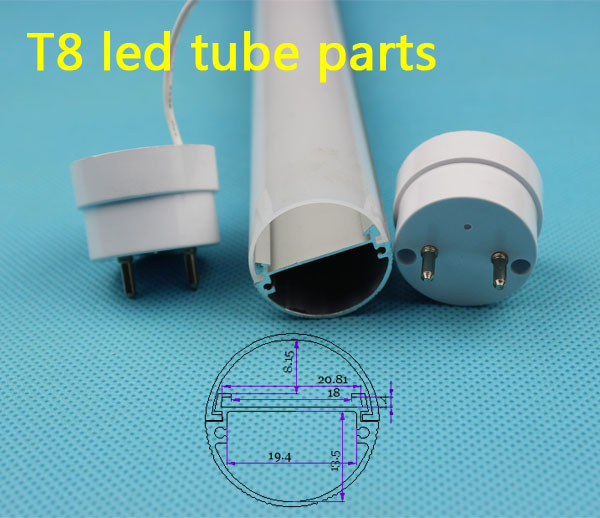

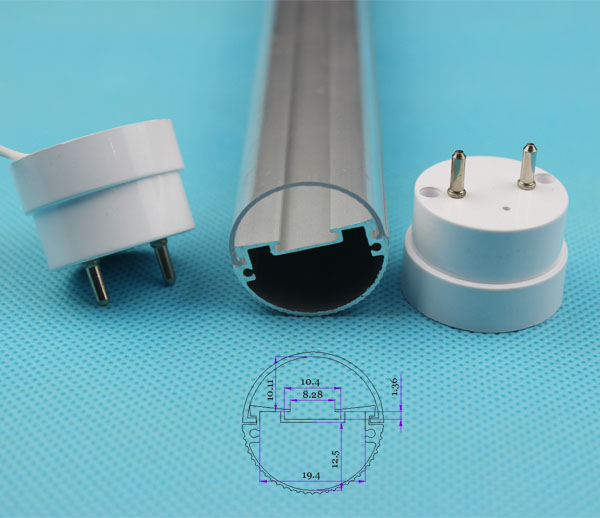

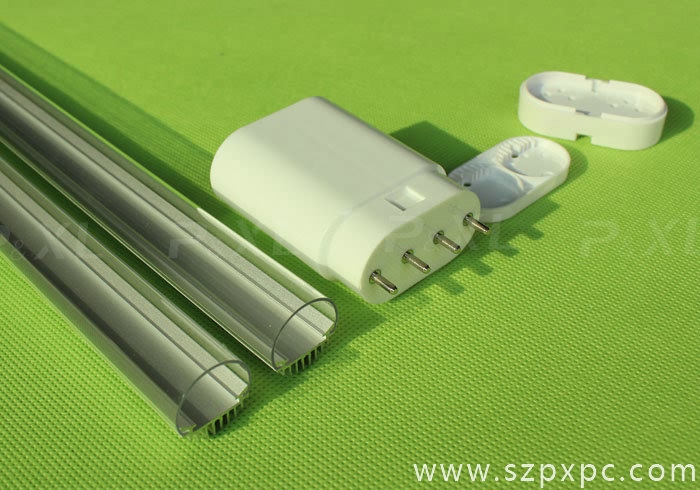

T8 LED tube light parts,led tube parts

T10 LED fluorescent lamp shell parts

MOQ :1000 piece

Lead Time :7 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union

Departure Port : Shenzhen

Product details

Supply Ability

- Supply Ability:14000 piecesWarranty(Year):2 Year

Packaging & Delivery

- Length:122 cmWidth:25 cm

- Height:25 cm

- Packaging:200 piece

Product Specifications

Product Description

You May Like

- Free Member

- Trade Assurance

Business Type : Manufacturer,Trading Company

Company Location: GUANG DONG

Year Established: 18YRS

You May Like

-

T8 LED tube light parts,led tube parts

-

T8 led tube housing

-

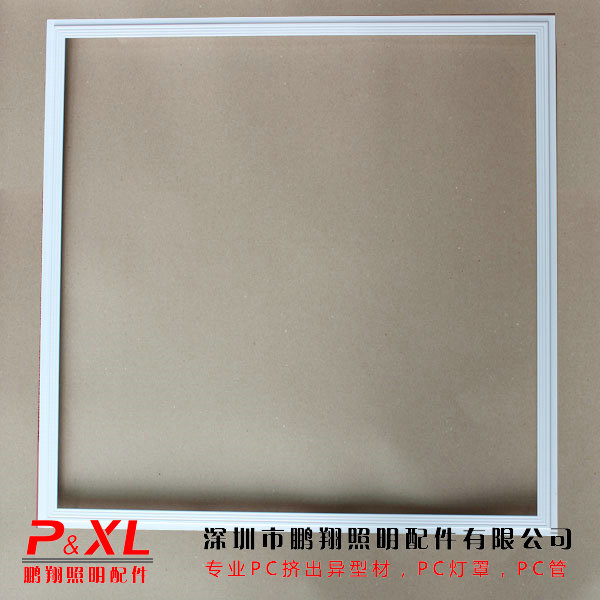

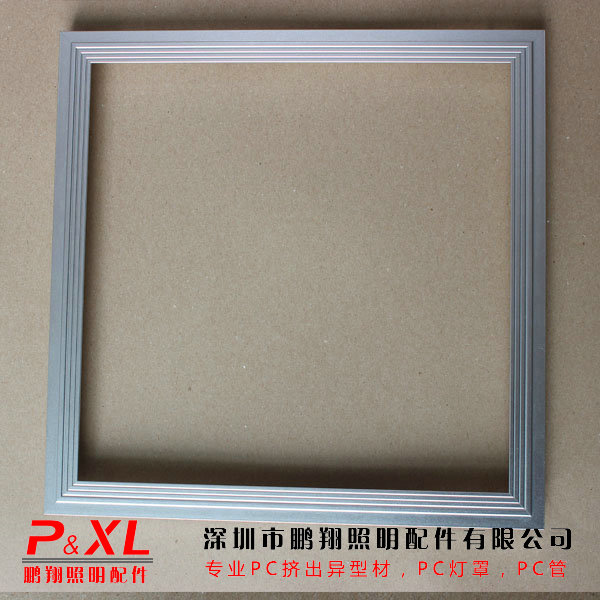

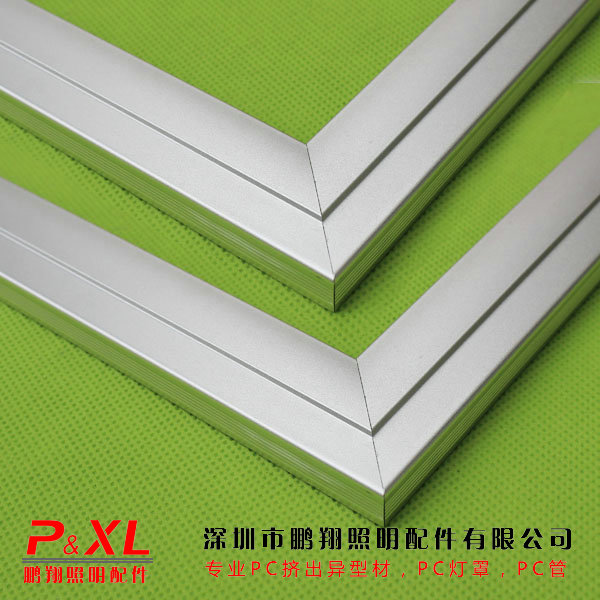

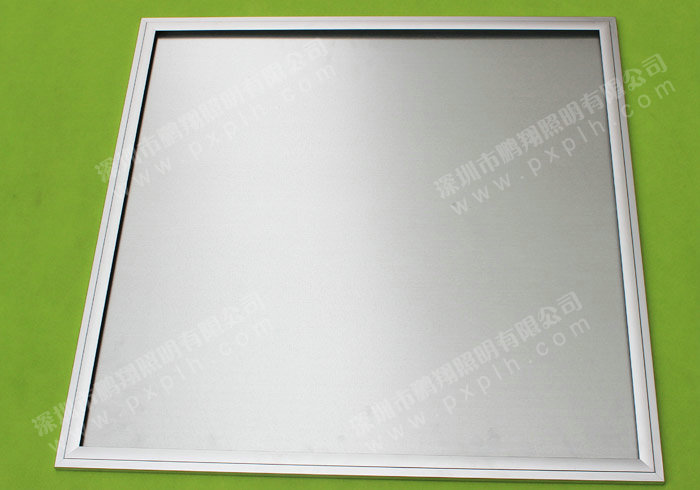

White panel lamp bracket,panel light housing

-

300*300 panel light aluminum frame bracket.

-

lamp panel aluminum frame

-

2G11 lamp housing,U type LED fluorescent lamp housing

-

Built-in power supply socket 2 g11 fluorescent lamp accessories

-

2G11-2--Lamp fittings,Flat lamp shell

-

LED fluorescent lamp and -2G11 lamp

-

Panel lamp housing,Panel light fittings